Dont Make Request Again Component Did Mount

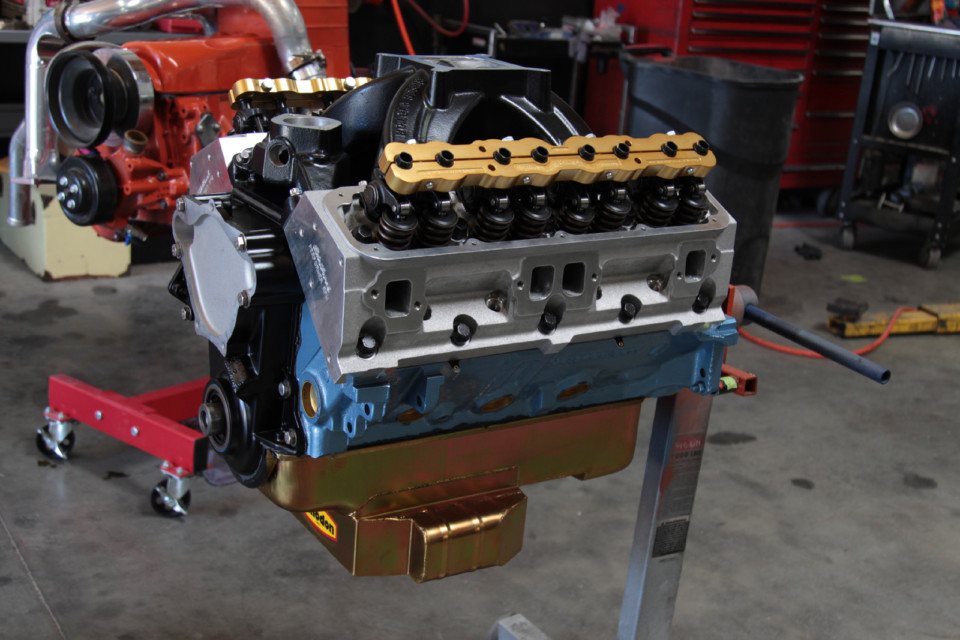

Nosotros've finally completed our 408ci stroker small-block Mopar build for Project Rails Assail. We did a little mixing and matching, but weren't exactly pioneers in the LA cake/Magnum head build. We did observe a few things that were not but important to the build, simply not well known in the community. What that means is, every time we rounded a corner, nosotros were met with unanswered questions.

Nosotros've finally completed our 408ci stroker small-block Mopar build for Project Rails Assail. We did a little mixing and matching, but weren't exactly pioneers in the LA cake/Magnum head build. We did observe a few things that were not but important to the build, simply not well known in the community. What that means is, every time we rounded a corner, nosotros were met with unanswered questions.

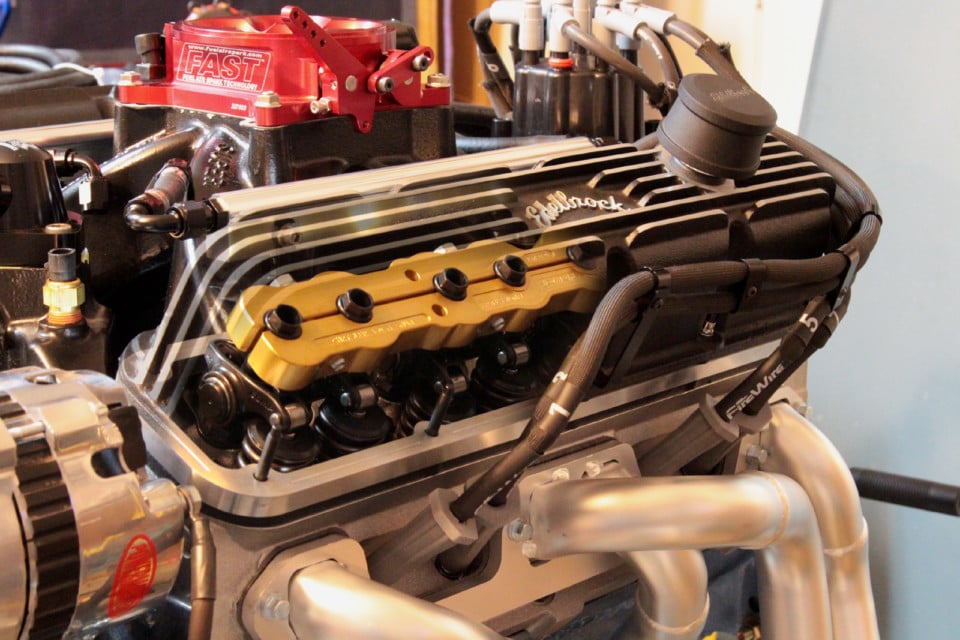

For example, using rocker-arm stud girdles was suggested, but nobody could directly united states to valve covers that would clear them. Nosotros aren't the first ones to use these parts, simply nosotros had to find a solution on our ain. We reached out to other builders, shops, manufacturers, and finally stumbled upon the solution. This article is to help others with our discoveries.

We knew nosotros were already on a different path by starting with annihilation other than a Hemi or a large-block. Our unorthodox path took several turns forth the way to the completed build. Information technology was highly recommended by Mopar enthusiasts to apply a 1970-1973 block. They're getting harder to find, and sometimes the price isn't worth the chance of finding out the block is croaky. We establish a 1973 block from a friend in Dulzura, California. Luckily, they let the states take information technology for a great toll.

Breathing is important, so we opted for Edelbrock'south Magnum heads. Their improved menstruum characteristics and compatibility with the Chevy 1.6-ratio roller rockers that we received from COMP Cams made them ideal. Nosotros counted on Scat Crankshafts for our rotating assembly with custom JE Pistons. After a few months at the machine store, the build was ready to commence. Beneath, we'll share some secrets and tips, in case you lot determine to perform a similar build.

Play a joke on Parts To Enhance The Build

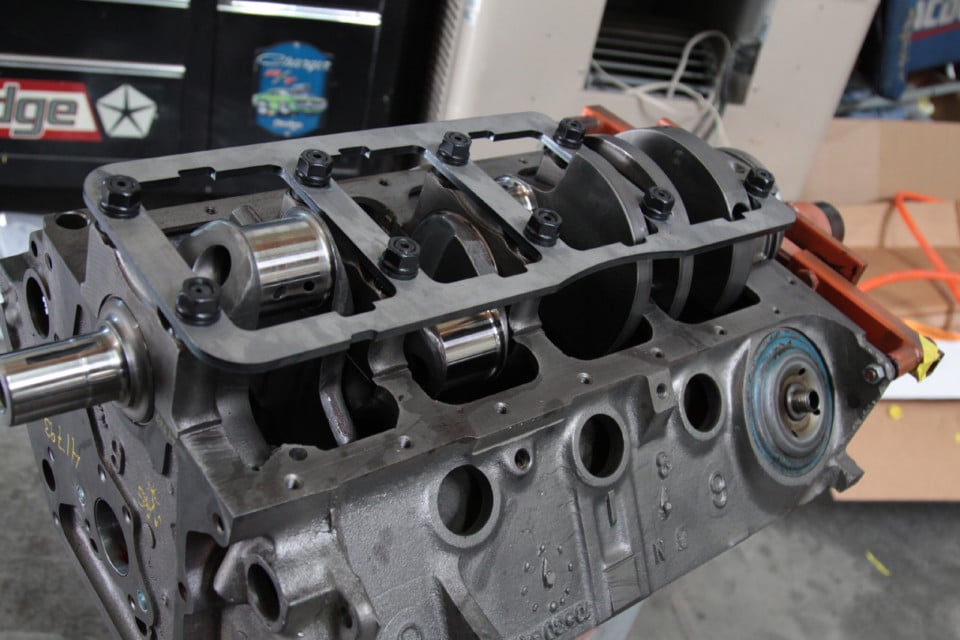

Main Stud Girdle

From: Hughes Engines

Part #: HUG 7382K

Toll: $326.88

It would be overnice to have the money for an R3 race-block, just the best blocks are either too expensive or too difficult to find. A 340 build would have been ameliorate, only who can detect a buildable 340 cake these days? 1 expect at Hughes Engines, and nosotros found a main-stud girdle to help tighten upwardly the lesser stop. The girdle can mountain in one of two ways: by machining the caps flush with the girdle (preferred) or using spacers.

At that place are kits available to convert to a iv-bolt master, only drilling into the cake'southward lower webbing is rumored to weaken the block. Nosotros opted for the stud girdle instead. The girdles are very affordable, and is a wise addition if y'all're heading past the 400 horsepower mark. David Hughes told usa, "I've had several customers with 700 horsepower naturally aspirated builds, and they've been doing but fine."

What you don't see: designed for flush mounting (preferred) or spaced, y'all want to ship this girdle to the motorcar shop that is prepping your cake. They tin auto the caps down flush with the girdle for more strength and stability.

Nosotros're non interested in launching on a sticky track with viscous tires, at "I tin can't hear you" RPM. In other words, we aren't concerned with living our Belvedere'south life "ten seconds at a time." Nosotros do programme so see some high numbers, only nosotros'll leave the "1,000 horsepower" to the braggarts. We're not just about numbers here – we're virtually driveability and usefulness.

We've been told that a windage tray is a overnice addition. However, nosotros also heard that one used in conjunction with a main stud girdle is a chip of a pain and tin be problematic, then nosotros chose to stick with our original plan.

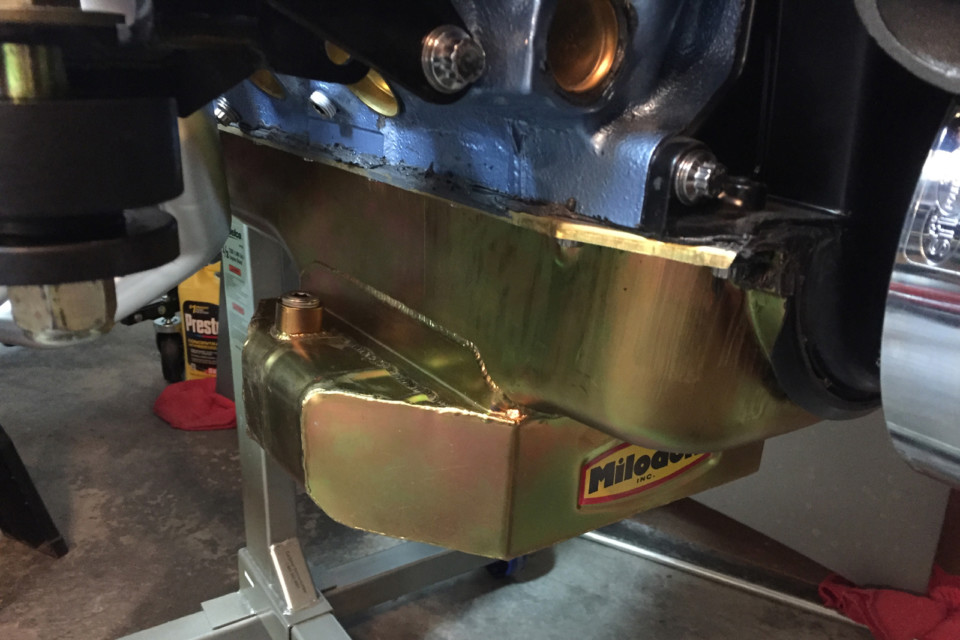

Road Race Oil Pan

From: Milodon

Part #: MIL-31595

Toll: $469.95 at Acme Racing Equipment

If you simply race your auto a couple times a yr, you lot should still make sure to build it with that in mind. Information technology's ill-advised to expect your street cruiser to handle the penalisation those trips to the rail will dish out. Our initial build was a slightly warmed-over street build. A few times at Willow Springs we noticed the oil-pressure level gauge dancing on the lower psi readings during hard cornering.

We opted for a true road-race pan from Milodon to gainsay that potential rod-tossing risk. Milodon had the only truthful road-race pan we could find. What makes this pan different from a standard deep-sump pan or a drag race pan is the inexplainable. Drag race pans have baffling to combat the sudden rush of oil heading towards the back of the pan at launch. Conversely, route race pans have baffling that keeps the oil in the pickup surface area during hard cornering.

What you don't encounter: five trap doors/gates, three deceleration gates, and two lateral gates to continue the oil near the sump and not sloshing effectually, all while holding half dozen quarts of oil with better ground clearance.

Another advantage of the Milodon pan are the side kickouts that let for a total vi quarts of oil. It does and so without increasing the vertical limitations a lowered car will have. Information technology is also a mid-sump design like the original pan (trucks and vans had rear sump) and will clear the manufacturing plant K-member. That includes 1967-1973 cars with later Thousand-members. With our Control Freak tubular Thousand-fellow member, the Milodon pan volition just clear the Flaming River steering rack in the early B-trunk.

A Melling oil pump (Part # M72HV) and Milodon pick-upwards (Function #: MIL-18343) are too required, both of which can be purchased from Superlative Racing Equipment for $60.89 and $62.95, respectively.

Oil Filter Relocation Kit

From: Hamburger'due south Performance Products

Part #: HAM-3373

Toll: $292.99 at Summit Racing Equipment

Many of yous know, irresolute your oil can be a mess if you have a Mopar small-scale-cake with headers. The filter is directly above the secondary tubes, and the area is tight. A stubborn oil filter can be hard to remove no matter how careful you try to be. A few drops of oil will collect around the tubes just earlier the collector, making it near impossible to clean up.

Once you beginning the engine, a worrisome smell accompanied by smoke will cause your middle to skip a beat. Sure, some people are experts, just a cloud that looms over some of us has a slightly blue tinge to it from all the times we smoked our headers.

What you don't meet: a mess all over your expensive, ceramic-coated headers every fourth dimension you change the oil. It's and then much nicer to mount the filter remotely where it's easier to alter.

There are other oil-filter relocation kits on the marketplace, but we love the billet piece from Hamburger'south Performance Products. The "IN" and "OUT" are clearly marked on both components for an easy routing of the fluid lines. The unique attachment bracket allows you to clock the filter mount in numerous positions every bit well. This helps direct the fluid lines in various directions. The horizontal fittings – every bit opposed to vertical – give this filter mount a lower profile. All of this equates to increased mounting possibilities.

The kit comes complete with four direct 3/4-inch -16 ORB-type (O-band) barbed fittings and two sections of xv-inch braided, reinforced -12 hose to run betwixt the cake and your desired location. Y'all'll enjoy the ease of changing filters once you go remote.

Stainless Steel Oil Dipstick

From: Milodon

Part #: MIL-22060

Price: $64.95 from Summit Racing Equipment

The oil dipstick in LA engines is typically on the rider's side of the forepart timing cover. It's impossible to run a tube directly into the opening – the tube needs to ophidian around the front-drive components. Add the billet fuel-pump-encompass plate on our Billet Specialties Tru Trac front drive arrangement to the mix and you'll take a very difficult time installing anyone'due south dipstick tube. Milodon had the solution for us. After two failed attempts with an eBay dipstick tube, we succeeded with the Milodon unit in a few seconds.

What you don't see: two failed attempts with a solid tube and non getting the bend just correct to clear the new forepart drive components. An open terminate wrench for leverage and a dead accident hammer made this a elementary install.

At the base of operations of the cake, the dipstick will need to take a rather precipitous turn away from the timing encompass. With the flexible braided sleeve of the Milodon unit, we only used an open-end wrench for leverage and tapped on information technology to drive the end of the tube into the cake.

Rocker Arm Stud Girdles

From: Jomar Operation

Part #: JPP 1194

Toll: $177.00 from Hughes Engines

Our builder suggested that nosotros strengthen up the top terminate with a rocker arm stud girdle for this build. We searched the Cyberspace and information technology led us to Jomar Performance – the merely rocker-arm stud girdle that we could find for a Mopar small-block (it'due south non an SBC, you know). The stud girdle was designed specifically for the Edelbrock Magnum heads we're using – imagine that.

We fabricated friends with John Ansteth at Jomar Performance. If you decide to give him a call, y'all might every bit well sit back with a cup of joe and be prepared for a serial of fascinating stories of trial and tribulation about boat engines, horsepower, and the expert old days! He came up with the idea after buying a magazine with an article about breaking rocker-arm studs, and felt at that place had to be a better way. In 1966, a prototype for his own 1965 Corvette with a tired mill proved to exist beneficial, increasing his RPM and functioning – and he contacted a patent attorney.

What you don't see: movement. This is the ticket for maintaining the duration your cam is rated at, because the rocker studs won't budge when the revs increase.

John said, "In virtually all engines with a stud-mounted rocker organisation, the rocker-arm stud is inclined towards the valve stem. When the rocker arm opens the valve, compressing the leap, the stud is deflected abroad from the spring towards the pushrod."

That deflection results in a decrease of effective 0.050 lift on valve open up duration. Connecting all of the studs together with the girdle eliminates that deflection and stabilizes the valvetrain. John tells u.s. the benefits to the peak end equate to a slight power increase. It also ensures that your rocker arms don't budge, eliminating the demand for constant valve-lash adjustments. On summit of that, John says, "The stud girdle is nearly maintenance gratuitous in one case correctly installed on an engine."

We asked if information technology'south always necessary, and he did say that balmy street engines will seldom benefit from a stud girdle. Many high-performance engines volition run okay without ane, but those with stud-mounted rockers will typically run better with the Jomar stud girdle. They've run a lot of dyno tests over the past 53 years, and have seen anywhere between 10 and 30 horsepower gains. He does warn about 'over-camming' an engine and using the girdle, suggesting to brand sure the cam is right for the rest of the engine.

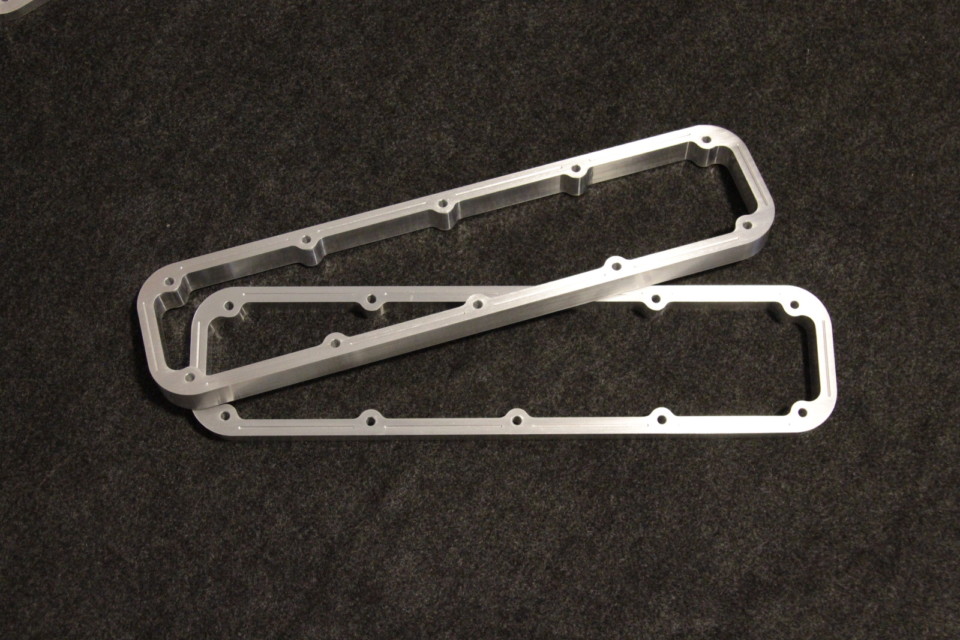

Valve Cover Spacers

From: Medice Manufacturing

Role #: 123 (1 inch), 120 (1/2 inch), 121 (3/eight inch)

Cost: $175, $135, $135, respectively

The rocker arm stud girdles were a nifty detect, simply that atomic number 82 us to clearance problems with the valve covers – everyone's valve covers. Nosotros asked around, trying to notice valve covers that could clear the stud girdles. We got the aforementioned answer from everyone nosotros asked: "I don't know – have them made." That wasn't giving u.s.a. much confidence, only the stud girdles were installed, and we weren't turning back.

We contacted a company that makes valve covers. They wanted united states of america to send them a cylinder head and valve comprehend in guild to build a new "alpine" valve encompass. That was too costly, so we contacted a local company that already had the Magnum design. After about three months of empty promises, we decided to hit the internet again. We eventually plant Dan Medice of Medice Manufacturing, in Cochranton, Pennsylvania.

What you lot don't see: gaskets squeezing out. Those grooves are what Medice calls its GasketLok feature; equally compression begins, the gasket 'locks' into place on the spacer and won't squeeze out, helping to keep oil inside.

They say timing is everything, and for us, it was perfect timing. Dan was but finishing upward his Magnum valve cover spacers, CNC machined from 6061 billet aluminum. Dan has been at this game since 2005. Afterward buying his ain machine store in 2011, he now has 35 engine families for which he builds spacers. He sent united states of america a couple pairs. After matching them up with a pair of Edelbrock's thick valve cover gaskets per side (Part # EDL-7593), we opted to install the 1/ii-inch spacers, which gave us the clearance nosotros needed.

Exhaust Headers

From: TTi Exhaust

Part #: TTi 340BE-C4

Cost: $840.00

When it comes to headers, yous can probably find a dozen or and so headers for a SBC. For Mopars, there are simply a few. One company that makes headers for Mopars only, is TTi Exhaust, in Corona, California. The quondam Polyhead 318 we were running was quite limited on performance parts, and TTi was the only company that made real headers for the A-block engine. Nosotros were able to loan our car to the team for test fitting of the Poly headers, so we were already familiar with the quality. It only made sense to get dorsum to them for headers for the new engine, and that was for a couple of reasons.

TTi focuses on the various aftermarket companies producing parts for Mopars by sticking with a specific marque. You'll notice references to Schumacher engine mounts, Command Freak Suspension, Edelbrock cylinder heads, et. al. The headers are mandrel bent on CNC machines, meaning the tubes aren't compressed where the pipes bend. They're fabricated to exact specifications each time. I other expanse of importance to TTi is consistency: they're consistent with the location and the clocking of the collector flange on every set of headers they make.

What you don't see: fitment issues. Staying with TTi Exhaust ways an engine swap is a elementary header bandy, and you won't demand to use any ball-peen persuasion to make your headers clear things similar the Milodon route race pan, the Argent Sport A41 manual, or your steering gear/linkage.

As with our case, swapping engines doesn't crave having a new exhaust system fabricated, because we are already running TTi headers on the old engine. The new TTi headers will bolt directly to our existing exhaust. They blueprint all of their headers to exist body-specific, meaning the collector flange is in a fixed location on every ready of V8 headers they make. If you're swapping from a small-block to a large-block, keep your frazzle and just purchase new headers for the new engine – they'll commodities right up.

You might think $840 is a lot for headers, but a custom prepare will run y'all even more to get this quality. They'll also clear our Silverish Sport Transmissions A41 automated, another mutual upgrade that Mopar owners take done over the years. The design isn't simply to route the tubes away from other components, the headers are designed to deliver the all-time possible functioning.

Some of these components aren't exactly new discoveries to the Mopar crowd, but they were very trick components for us. Some were difficult to find, and others were easy to find if you knew where to await. All of them are what helps brand our build a fiddling unique and prepare for the track – or our side by side trip to Vegas.

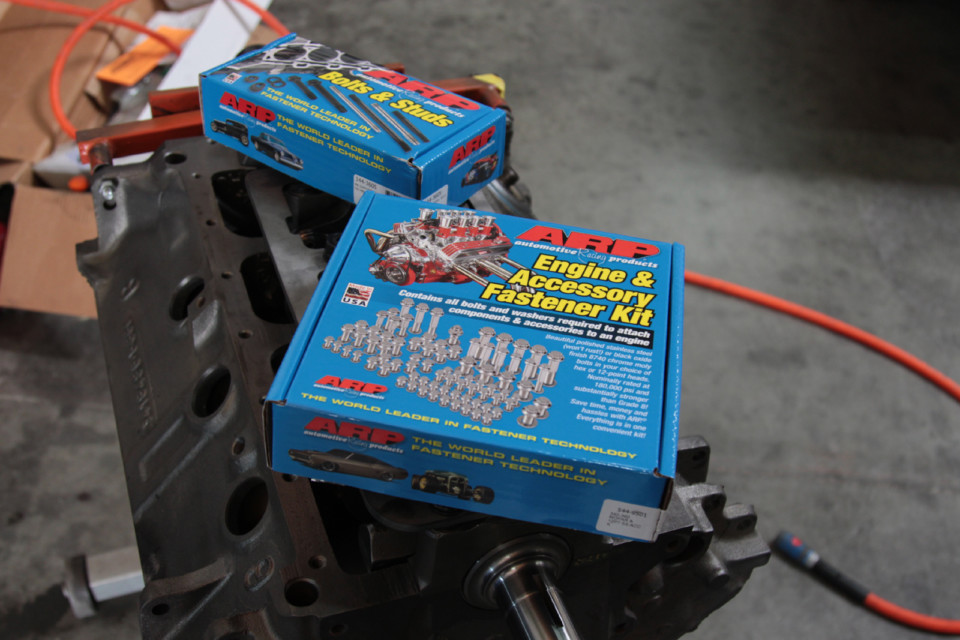

Nosotros would be remiss if we didn't mention some other component that's renowned in the automotive world: ARP bolts. We relied heavily on ARP to put this engine together, and nosotros used ARP nuts and bolts from the valve covers downwards to the oil pan, including engine mounts.

What you don't see: damage from close tolerances. ARP'southward 12-bespeak design allows for a smaller wrench/socket size for tighter quarters, like our coated valve covers. A six-signal nut required a larger socket size that rubbed, but the ARP hardware gave us better tool clearance, plus they're stronger and swell center candy.

We used ARP polished stainless steel 12-signal nuts and bolts to pretty-up our build. They're even stronger than the grade-8 bolts that you lot find at automotive and home-improvement stores. We likewise liked the fact that many nut and bolt combos use dissimilar wrench sizes, like our engine-mount bolts, and then we didn't need a matching pair of box-finish wrenches. Commodities sets are bachelor for many mutual engine families, in both polished or black oxide and with 12- or half-dozen-point bolt heads. The bolts are rated at 180,000 psi, which makes them the only selection for both good looks and strength.

We've spent a flake of time creating the next powerplant for Project Rail Attack. As they say though, Rome wasn't built in a day – and neither is an old-school Mopar. Until the next installment, bask the gallery below.

Source: https://www.streetmusclemag.com/tech-stories/engine/what-you-dont-see-tricks-behind-our-408-stroker-small-block-build/

0 Response to "Dont Make Request Again Component Did Mount"

Post a Comment