Galvanized Pipe That Can Be Used as Handrails

At that place are 3 master material types of metal handrails unremarkably used in construction. Beneath is a list and summary of each type:

– Fabric types bachelor are

-ASTM A53 (Carbon Steel Blend) Seamless and/or Welded in Nominal Pipe Size (NPS) of 1/8″ – 26″ of varying types and grades, Blazon E Class B being most mutual. 1/two″ (0.84″ OD) – 3/4″ (i.05″ OD) – 1″ (1.315″ OD) – 1-1/iv″ (1.66″ OD) – one-1/two″ (i.9″ OD) – 2″ (two.375″ OD) – 2-1/two″ (2.875″) – 3″ (3.5″ OD) – 3-1/2″ (iv″ OD) – 4″ (four.5″ OD) – v″ (5.563″ OD) – 6″ (half-dozen.625″ OD) – viii″ (eight.625″ OD) – x″ (x.75″ OD)

-ASTM A500 (Carbon Steel Blend) Cold Formed Welded and Seamless coming in circular, square, and rectangular sizes. The iv grades of ASTM 500 steel are A (45ksi), B (58ksi), C (62ksi), D (58ksi – heat treatment) and is based around tensile forcefulness among other strength properties (limerick, yield, elongation, etc). The sizes in this category are 88″ in size or less and with a wall thickness of 0.875″ or less. ASTM 500 tube for example, comes in mutual sizes of 1/2″ (0.84″ OD) – 3/four″ (i.05″ OD) – i″ (1.315″ OD) – 1-1/4″ (1.66″ OD) – ane-ane/two″ (1.9″ OD) – 2″ (two.375″ OD) – three″ (3.5″ OD) – 3-1/2″ (4″ OD) – 4″ (4.five″ OD) – 5″ (5.563″ OD) – half dozen″ (6.625″ OD) – eight″ (8.625″ OD) – 10″ (x.75″ OD)

-ASTM 501 (Carbon STeel Alloy) Hot Formed Welded and Seamless Piping – This pipe is similar to ASTM 500 but a hot procedure is utilized in fabrication. Also the ii grades are A (36,000psi) and B (l,000psi)

Connectedness types with the in a higher place materials is typically welded unless noted otherwise. A bulk of the cost when fabricating a railing system involves the grinding and sanding needed to dress joints. Welded joints are commonly graded by Type 1, two, iii & 4 with type 1 having the fewest visual imperfections and type 4 having the most.

Steel piping railing systems are either field painted or galvanized. Piping or tubing can exist supplied with either a black or galvanized stop. Field galvanizing is often accounted impractical due to workers protection, safe, and cost. When an engineer specifies galvanized pipe, either the pipe must exist hot-dip galvanized after fabrication (which is often plush due to size limitations) or employ pre-galvanized pipe with a zinc rich paint existence applied in the field over welds and abrasions.

Extruded pipe and drawn tube are bachelor in aluminum and are ordinarily used in piping railing systems. The main divergence betwixt pipe and tube is in dimensional tolerance and surface quality. Drawn tube pipe generally has tighter dimensional tolerance and fewer surface quality defects, while extruded pipe may non be as dimensionally strict and smooth. Welded pipe railing systems often exercise not require drawn tube fabric while flush fitting organization assembled mechanically might. Tube-quality pipe is besides used where an etched, anodized, or polished terminate is specified.

The two common types of aluminum piping textile are ASTM B 429 Aluminum

and Aluminum Alloy Extruded Piping and ASTM B221 Aluminum and Aluminum Blend Extruded Bars, Rods, Wires, Shapes, and Tubes.

Drawn Tube is commonly specified by ASTM B483 or ASTM B210.

Blend 6063-T52 is commonly used in railing systems and can exist bent without heating.

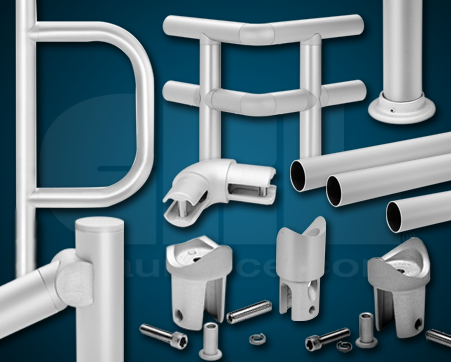

Alloy 6063-T832 has the smoothest surface and the all-time dimensional accuracy of almost any aluminum material; it is suitable for articulate anodizing without discoloration. Blend 6061-T6 has the aforementioned high strength every bit 6063T832 at less cost, merely doesn't bend every bit well and may tint yellow when anodized. Aluminum handrail pipe unremarkably comes in two sizes, 1-1/4″ (1.66″ OD) and one-1/two″ (1.nine″ OD) and accept wall thickness of 0.125″, 0.188″, and 0.25″. Aluminum rails connections are made by mitering, angle, welding, or using standard fittings.

Alloy 5356 or 4043 filler wire is used for mill finish aluminum. Alloy 5256 is used for rail that is to exist anodized.

If appearance is important, welds are footing, polished, and blended; otherwise (especially in structural applications) the aluminum is left untouched at the welded joints. Welding removes atmosphere and reduces forcefulness within one″ of a weld. Anodizing comes in articulate and colored finishes, with bronze beingness quite popular. Anodizing finish provides a durable, visually highly-seasoned, weather resistant surface. An Architectural Course I finish has a minimum Anodic blanket thickness of 0.7mils. An Architectural Class II finish has a minimum Anodic blanket thickness of 0.4mils.

Handrails are corrosion and heat resistant iron-based alloy containing at least xvi% chromium, along with nickel and other alloy elements. Stainless steel is grouped into numbers 200, 300, and 400. The stainless used for railing systems and other architectural applications is typically grade 304 and 316. Both grades are available in 304 piping and tubing. The most economical course of stainless railing systems is welded tubing and is typically non-annealed, non-pickled, and not-pressure tested. This product is ASTM A554 (Welded Stainless Steel mechanical Tubing) is available in the same OD every bit stainless pipage, merely can be had at a lower cost.

What is referred to as a #iv stop (full general purpose bright polished cease) is well-nigh commonly used and readily available, but other finishes can exist had like not-reflective mill finish and bright annealed.

#4 finish is easily matched in store or field in terms of terminate blending afterwards welding or removal of surface blemishes.

Handrails posts tin be anchored on horizontal surfaces by circular flange and acnhor, coring and grouting, slip fitted metal socket, and welded to anchored plate.

Some common types of post bases are apartment flange, raised flange, tapered flat flange, rectangular flat flange. Connections can be either welded or non welded (mechanically attached with fittings).

Wall-mounted handrails are commonly attached to walls with handrail bracket; extruded, formed, cast, or machined.

Source: https://constructionmentor.net/metal-pipe-railing/

0 Response to "Galvanized Pipe That Can Be Used as Handrails"

Post a Comment